testing mechanical seals|seal strength vs integrity : service A mechanical seal leak test is a procedure to check for leaks in mechanical seals, which are used to prevent fluid leakage around rotating . 26 de mai. de 2023 · PayPal is the most complete payment method for online casino players, regardless of what kind of online casino games are your favorite, be that Live Roulette or any other casino game. Due to its nature and its policies, PayPal is not available worldwide, and to make matters worse for online casino players, PayPal is not .

{plog:ftitle_list}

WEBpessoa. barba. homem jovem. corpo. rosto. Encontre imagens de Homem Nu Sem direitos de autor Atribuição não requerida Imagens de alta qualidade.

A mechanical seal leak test is a procedure to check for leaks in mechanical seals, which are used to prevent fluid leakage around rotating . The design of a mechanical plunger seal developed and made for high-pressure tests on a Weir SPM (USA) test bench, the test procedures, and the measuring instruments used are described. It is shown that a mechanical plunger seal 70 mm in diameter is capable of operating at fluid pressures of up to 50.4 MPa.

We’ve been campaigning to have this changed, and we voluntarily submit our mechanical seals to a far stricter test. To prove that the current test does not reflect best practice, we manufactured a sealing assembly which was able to .Whether in-house testing or field trials, we are able to reproduce ideal and worst-case operating conditions, recording seal integrity, as well as monitoring pressure, speed, temperature, and a number of other performance factors. .AESSEAL ® holds the world's most comprehensive standard inventory portfolio of mechanical seals, bearing protectors, seal support systems and packing. AESSEAL ® operates from 235 locations in 104 countries, including 9 manufacturing and 58 repair locations, and has more than 300 customer service representatives who visit industrial plants .

To demonstrate the performance capability of a particular mechanical seal design in an objective way demands some means of referencing an adequately arduous test condition appropriate to the seal in question. The minimum point on the friction coefficient versus duty.The mechanical seal Mechanical seals have the purpose of preventing leakage of a fluid (liquid or gaseous) through the clearance between a shaft and the fluid container. (Fig.1) The main components of a mechanical seal are the seal rings on which a mechanical force is acting, generated by springs or

API 682 Seal Qualification Testing. In order to provide end users with a high degree of confidence in mechanical seals designed in accordance with the standard, API Standard 682 requires that manufacturers conduct 'Seal Qualification Testing' (SQT) prior to market availability to a defined set of criteria, and sets minimum performance requirements for various seal .

Compression seal example. A seal is a device or material that helps join systems, mechanisms or other materials together by preventing leakage (e.g. in a pumping system), containing pressure, or excluding contamination.The effectiveness of a seal is dependent on adhesion in the case of sealants and compression in the case of gaskets.The seals are installed in pumps in a wide . Mechanical seals are devices that are used to provide a seal at the point of entry or exit of a rotating shaft. From: Fluid Machinery Congress 6-7 October 2014, 2014. . There are techniques for testing for leakage of the inner seal by measuring the vent space pressure through the seal liquid surge port. This should be essentially atmospheric .

seal testing techniques pdf

hardness test kit hanna instruments

The aspirating seal design utilizes a thin air film established from the pressure differential (Delta P) across the seal to prevent rubbing between stationary and rotating seal components, Over . Certificate of Conformance for Freight Container Mechanical Seal Testing . Seal Classification: High Security . Customer: American Casting and Manufacturing Corporation 51 Commercial Street . Dayton T. Brown, Inc. certifies that 26 samples, 5 for each test and 1 for measurements, of the Seals referenced above were subjected to the following .

Micro Seal Is One Of The Leading Designers & Suppliers Of World-Class Mechanical Seals, Seal Support Systems For Pumps, Compressors, Agitators, Mixers, And R.Mechanical containment seals can be contacting or non-contacting. Full definitions of these types of seals can be found in API 682 4th clauses 2.1.18 and 2.1.56. . It is advisable to test seals in service at regular intervals. Static testing of the seal is recommended. The intervals may vary dependent uponEagle Industry is a comprehensive manufacturer of mechanical seals and equipment products. Our technologies and products are used in the automotive, marine, rocket/aircraft, and various industries around the world. . measurement, verification test, and so on. Source: “Current status and future prospects of a wind/hydraulic machinery .

My apologize, I did not check the sentences was many typo errors. Let me rewrite . I am concerned with a mechanical seal hydrostatic test, seal is going to be installed in internal gear pump ( Plan 11 and 62) having glands, quench and flush without instrument. Assembly & Testing: Thorough post-assembly checklist for each mechanical seal before dispatch, ensuring every product is fit for purpose upon leaving the factory. Inventory & Customer Service : Strategic maintenance of a .

hardness test kit hi 3812

C. Types of Mechanical Seals Based on Seal Position. A mechanical seal is classified into the following two types based on seal position. Internal Mechanical Seal; External Mechanical Seal; 1. Internal Mechanical .The mechanical seal itself is the interface between the static and rotary portions of the seal. One part of the seal, either to static or rotary portion, is always resiliently mounted and spring loaded to accommodate any small shaft deflections, shaft movement due to bearing tolerances and out-of-perpendicular alignment due to manufacturing . In general, mechanical seals should be inspected regularly and replaced when signs of wear, leakage, or damage are observed. In conclusion. Understanding the different types of mechanical seals for centrifugal pumps is essential for optimal performance and longevity. Consider factors such as the application, environment, and budget when .Stein Seal offers comprehensive mechanical seal testing services to ensure performance and reliability under demanding industrial conditions. . Our custom inter-shaft rigs feature two independently controlled spindles that allow testing of inter-shaft seals, such as piston rings. Rotation: 30,000 rpm on the high-speed spindle, 18,000 rpm on .

SEAL Physical Screening Test ( SEAL PST ) The ASVAB and AFQT are used to assess a candidate’s mental sharpness and ability to learn. While the C-SORT is used to screen his maturity and mental resilience. . However, if your Mechanical Comprehension ( MC ) score is more than five points below the minimum, you will not be granted a waiver.EagleBurgmann mechanical seals and seal supply systems, referring to the seal classification parameters and piping plans . One of the test rigs for runnning seal qualification tests according to API at EagleBurgmann. Content. Category Arrangement Configuration Seal type Spring position 1 2 3 1 1CW-FX A Rotating ASME B73.1, ASME B73.2, API 676 .

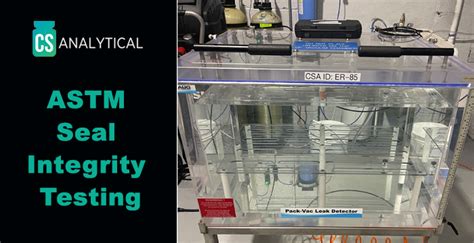

Welcome to our comprehensive guide on mechanical seals, an essential component in many industrial applications. Whether you're an experienced engineer or new to the field, understanding the intricacies of mechanical seals is crucial to maintaining efficient operations and minimizing downtime. In this guide, we'll delve into the signs of a .To test the integrity of mechanical seals fitted with a secondary containment seal. This document is general in nature and does not refer to site specific requirements. The site has the responsibility for ensuring that tests are carried out. Access this Resource.mechanical seals in petrochemical, chemical, and pipeline services worldwide. It has combined the aspects of seal design, testing, standardization, and applications to provide the users and OEMs alike with a common source of information for mechanical seals. As seal technology has advanced, the standard has expanded to incorporate

Three types of test rig were used: a seal friction-measurement rig, a set of seal wear test rigs, and a precision seal material test rig. Rig Type I : Mechanical seal friction rig. Mechanical seals are run in pairs with pressurised test fluid between the two seal. The seal housing ismechanical seal faces also require some (very small) lubricating or cooling fluid across the faces, to form . Recent testing has shown that double seal life is virtually unaffected by process upset conditions during pump operation. Examples are Dura RO and Crane double 811T. d) Double Gas Barrier (pressurized Dual Gas) Seals:

seal testing techniques

hardness test kit hi3812

• How LVDTs Work: an interactive explanation• Phasing Explanation• LVDT models and applications Ver mais

testing mechanical seals|seal strength vs integrity